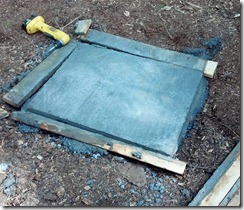

It’s not much, but it will soon be the foundation for the Little Free Library. I’m wondering if this will be the heaviest little library in the country. The two steel pipes are sunk into the earth (12 inches) and then extend through the 3-1/2” concrete slab. These are the sleeves for the two steel columns that will hold everything together.

These columns are shown below. They’re about eight feet long.

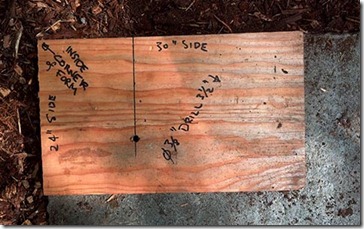

This frame (above) is lying on the ground in its fixture, all set up for welding. The 2 x 4s are spacers. When you use pieces of wood to help you weld, no one will ever take you seriously.

I never claimed to be a welder

This is a good example of why I’m not a welder. In this embarrassing picture, I’ve attached a cross brace to one of the columns.

With practice, I’ll do better. Not good, but better.

The library (newspaper) box

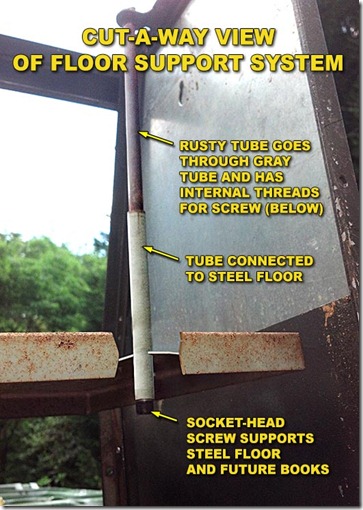

The inside of the box will rest on (and be attached to) two heavy steel angles. I’ll use the existing holes in the newspaper box to drill the matching holes in the angles. The red spray paint marks the steel below (for drilling).