Making a Little Free Library from an old newspaper box is more difficult than I expected. It’s steel—and that means drilling through metal, welding, grinding, and riveting. It also means threading screws, rods, and holes.

But at least it’s already designed for the task: holding a lot of heavy paper. Newspapers . . . books, it’s all the same when it comes to weight.

So today’s task was installing floors for the upper and lower levels, like a little two-story building.

I had planned on wooden shelves like the one being test fitted on the lower level. But for the upper part I decided to use the very practical floating steel platform that was part of the original equipment.

If the platform fits, use it

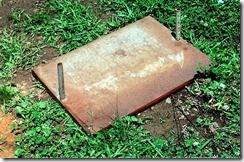

Below is the metal platform on my neatly manicured lawn. Note the two steel tubes welded to the platform. These tubes fit over two smaller tubes and have heavy-duty springs to support a lot of newspapers. When more papers are added, the springs stretch and the platform moves into the lower part of the paper box. As newspapers sell, the platform moves up.

I didn’t want a floating shelf, so I removed the springs for use on the tin man. You’ll see that on a future episode.

Making a moving shelf be still

All I had to do was make a fixed shelf from a spring-loaded platform.

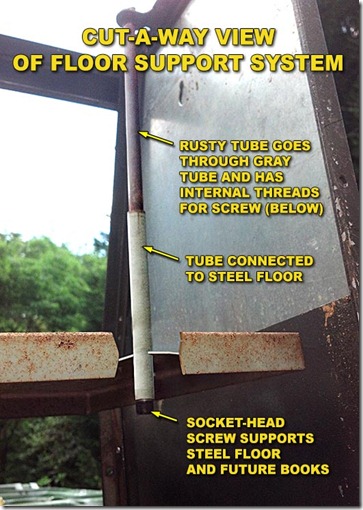

This cut-a-way view shows how the shelf is attached to the gray tubes. The whole thing is supported by two rusty tubes that go through the gray tubes. The rusty tubes were threaded at the bottoms to accept 3/8” x 24 socket-head screws.

Four pop rivets attach the front of the shelf to the frame. I mention this because I just got a new pop-rivet tool that makes the job much easier.

Finally, here’s a full view of the newspaper box on a temporary work stand.

That’s all for now.

Next time (maybe): How to re-engineer a door . . . several times.

No comments:

Post a Comment